Reusable Space Debris Collector to Transform Industry

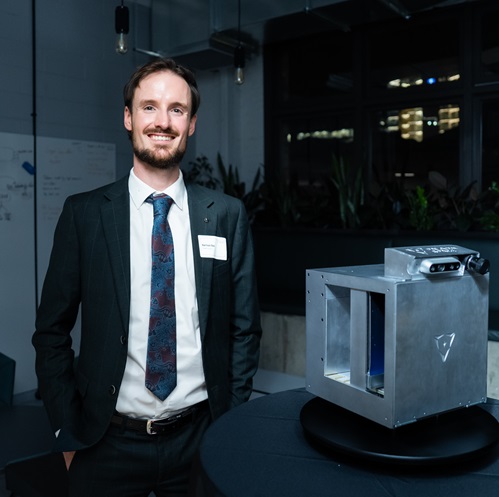

Paladin founder and CEO, Harrison Box, with Triton

University of South Australia based startup Paladin Space has demonstrated the world’s first space payload capable of capturing debris from multiple targets and storing it on satellites for recycling, reducing the cost of space debris removal and making the process more sustainable.

The company showcased their technology, called Triton, at a private demonstration event yesterday at UniSA’s Innovation & Collaboration Centre (ICC).

The next steps will be to demonstrate the technology in orbit, secure pilot customers and perform qualification testing for a space mission. The company is also expecting to share news of an overseas expansion in coming months.

South Australian Treasurer and Minister for Defence and Space Industries Stephen Mullighan says the potential of this innovative product demonstrates the impact South Australian based space startups are having in leading advances in space technology.

“Space start-ups play a critical role in accelerating the growth of the South Australian space industry and strengthening our economic resilience and relevance,” Minister Mullighan said.

“Paladin Space’s innovative technology, which has been developed right here in South Australia, is a perfect example of what’s possible when you foster an environment that nurtures bold ideas. It’s an example of homegrown ingenuity where South Australia is developing innovative ideas aimed at solving global challenges.”

Space debris is a growing issue that poses significant threats to satellites and space missions. The large volume of debris, combined with its high velocity, creates a collision risk with potential to damage satellites and space infrastructure.

A report by Northern Sky Research found that the ‘In-Orbit Servicing Market’ is expected to reach $4.7b by 2031, and roughly half of that market is debris removal and salvaging.

Founder of Paladin Space, Harrison Box says their product will be able to capture multiple pieces of debris in a single mission.

“Triton will make the process of debris removal more sustainable and cost effective while also being able to eject its contents on space targets, preserving the spacecraft in orbit to be reused for other missions,” he says.

Their solution means Triton will eject its contents from the parent satellite at a very specific time so that it’s trajectory will not interfere with anyone else’s satellites. Shortly after ejection, Triton will descend into the Earth’s atmosphere, causing it to burn up completely within a matter of hours.

The team are designing Triton to be compatible with future in-orbit recycling solutions so its contents can be delivered in-orbit as materials for manufacturing.

“We are designing Triton to be able to dock easily with these in-orbit manufacturing stations so that the contents it collects can be recycled into metal rods or sheets for manufacturing satellites,” Mr Box says.

“Not only is this practice sustainable, but incredibly cost effective for satellite manufacturers to ‘skip’ the launch phase of a mission and simply build their assets in space.”

The Triton container is designed to capture many small pieces of debris such as fragments from collisions, however, the product is scalable depending on the mission. If a customer wants a larger volume, they could achieve 600mm (0.6m) cubed, or smaller missions may only require 300mm (0.3m) cubed.

The Paladin team with UniSA’s Peter Stevens

Paladin Space participated in UniSA’s space accelerator program Venture Catalyst Space in 2023, supported by the South Australian Space Industry Centre.

Deputy Director: Business Incubation at the University of South Australia Craig Jones says the novel technology has the potential to make a huge impact on the space debris market.

“Triton is on course to revolutionise the space debris industry and contribute to manufacturing in space, a mind-blowing proposition. We look forward to seeing it in action one day soon,” Jones says.

“From placing second at an ICC global space hackathon, to participating in the Venture Catalyst Space program in 2023, we are incredibly proud to have played a small part in supporting this team to build their enterprise,” he says.

Box says UniSA’s support and infrastructure continue to be instrumental to the success of his business.

“The advice I received in the early days helped to shape everything from our pitch deck to the financial accounting for our business, including areas like employability, beach-head markets, problem validation and general customer acquisition practices.

“Having an office space to prototype and run our business from was also a game-changer that allowed Paladin Space to be put on the map, and I am still honoured to be a resident at the Innovation & Collaboration Centre – despite the team growing larger.”

Box says he plans to keep his company headquarters in South Australia as they grow for as long as the government continues to support the space industry.

Venture Catalyst Space, has supported 40 startups that have collectively raised almost $43 million in additional investment and grants, while creating almost 240 space jobs.

About Harrison Box:

- Box has a Masters in Aerospace Engineering with first-class honours from the University of Glasgow.

- He spent a year of his study at the University of California where he led a team to design and build a liquid rocket engine test stand in the Mojave desert.

- During his time at university he worked as a Powertrain Engineer at Nissan and a Avionics Engineer for a flight hardware company before becoming a Systems Engineer for BAE Systems. He spent two years working for multiple fast-jets in various countries, then was a Concept Engineer doing a variety of R&D work on military fast-jets for the remaining year before moving to Australia and becoming a Senior Systems Engineer for a novel radar project.

https://www.unisa.edu.au/media-centre/Releases/2025/world-first-reusable-space-debris-collector-set-to-revolutionise-sector/